RUBBER BALLOON FOR THE SUCTION HOSE OF THE WATER PUMP WO2024/039258

PATENT IS NOW FREE. No national phase application has been filed for patent WO2024039258 - RUBBER BALLOON FOR THE SUCTION HOSE OF THE WATER PUMP.The WIPO-PCT application does not include important technical details that are currently secret and are important for the future manufacturer.

The use of rubber balloons instead of a non-return valve at the beginning of the suction hose of a water pump is described in three applications (patents).All three applications describe a way to use rubber balloons (decorative balloons for Christmas or celebrations) at the beginning of the suction hose of the water pump instead of a non-return valve.This entire system is used in narrow wells of 5/4 inches - 6/4 inches, such as in the pipes of hand water pumps and in other cases where there is a need for it. The rubber balloons that will be factory-made will be cylindrical in shape and have dimensions that correspond to the cross-section of the suction hose.The non-return valve is installed at the pump outlet.

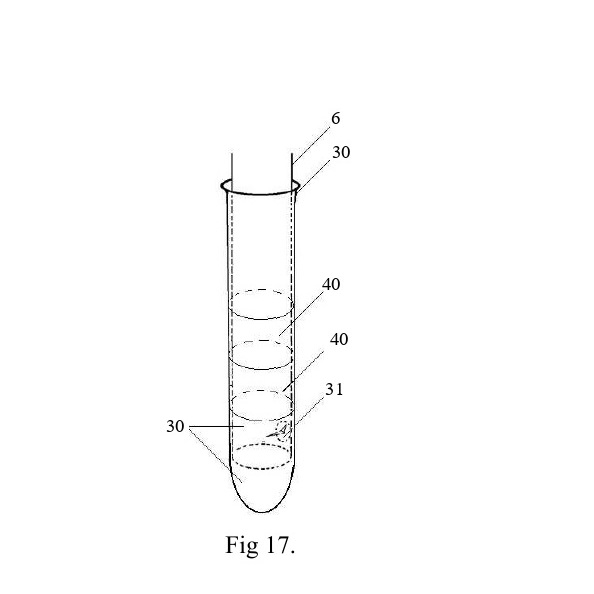

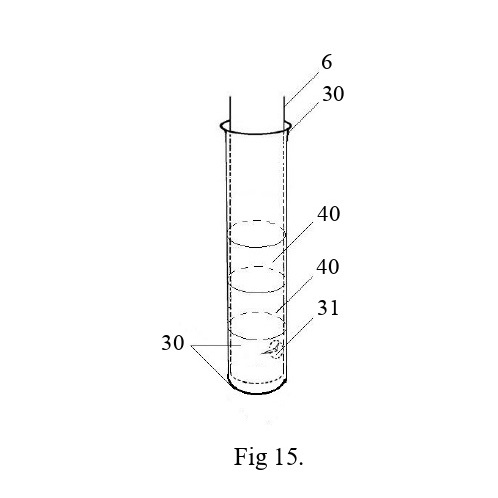

Figure 17 shows the appearance of the rubber balloon 30 where the pump 10, the suction hose 6 and the balloon 30 are filled with water. Pump 10 has not yet been commissioned. The rubber balloon 30, together with the beginning of the suction hose 6, is immersed in the water in the well 1. The beginning of the suction hose with the top of the balloon is at the working depth. As the weight of the water from the suction hose 6 and the pump 10 is greater than the water pressure from the well 1, the rubber balloon 30 protrudes towards the well 1. The height of the water column is slightly less than 8 m, so the pressure on the balloon from the suction hose 6 is towards the well less than 0.8 bar. Since the entire system is filled with water, the pump 10 can be put into operation.

The system is primarily intended for centrifugal pumps. First, a rubber balloon is attached to the beginning of the suction hose. Then, the system is filled with water from a height of up to 1 meter. This fully water-filled system is lowered into the well. When the pump is started, the rubber balloon bursts, creating a continuous water column from the well to the pump without any air. Since a non-return valve is installed at the water pump outlet, water cannot drop to the bottom of the well when the water pump is not in operation.The picture shows the appearance of the beginning of a suction hose filled with water submerged in a well, with a rubber balloon, before the balloon bursts and while the pump is not yet operational.

The application was submitted as a supplement to the international application WO2024/039258.

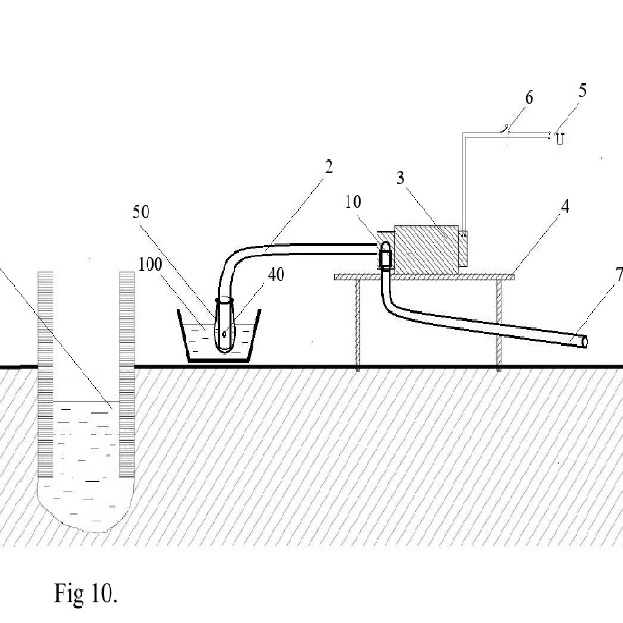

There is a significant difference between the procedure of lowering an empty suction hose sealed with a rubber balloon into the well and then filling the entire system with water through the filling hole, and the procedure of lowering a water-filled suction hose sealed with a rubber balloon into the well. When the empty suction hose is lowered into the well and the entire system is filled with water, the water gains kinetic energy described by mgh = mv2 /2, ( m*v*v*1/2 ) which at a height of h = 8m, results in a speed of v = 45 km /h, neglecting friction. Because of this, the balloons sometimes burst during the pouring of water, so it is necessary to fill the entire system with water from a height of less than 1m in order to reduce the kinetic energy of the water.

Unlike the previous application, this application describes the use of rubber balloons in self-priming pumps that use a balloon at the beginning of the suction hose. First, the pump itself and the system are filled with water. Then the rubber balloon is mounted below the surface of the water, and then the suction hose, which is closed by the rubber balloon and is full of water, is sunk into the well. Self-priming diaphragm pumps do not require a check valve at the pump outlet.

This procedure is characterized by the fact that you need a self-priming pump, a suction hose and just another rubber balloon to start the pump, which is used to pump out water up to 8m deep.

This application is in the national phase in the Republic of Serbia. The application was submitted as a supplement to the international application WO2024/039258.

When the pump is used above the pipe of the hand pump, the difference between the balloon system and the check valve at the beginning of the suction hose can be 20-40% in flow, since the effective area of the suction hose with the balloon at its beginning is more than 50% greater than the effective surface area non-return valve. (see picture) .

By using rubber balloons for the suction hoses of the water pump, the work of the plumber on the installation of the water pump is redundant.It saves on the work of the master (about three working hours), as well as on additional parts that connect the pump and the suction hose. Also, the pump is not fixed to the suction pipe so that it is possible to dismantle it after each use.

Click on the link to download or view the pdf document:PCT/RS2023/000010 En WO2024/039258

Click on the link to download or view the pdf document:P-2023/0779 En RS

Click on the link to download or view the pdf document:P-2023/0684 En RS

Click on the link to download or view the pdf document: EPO-ISR for WO2024/039258

Publication link WO2024/039258

Boban Stojanović

Sindjelićeva 3/10

35230 Ćuprija

Serbia

mail: boban_stojanovic@protonmail.com

Landline Phone / fax: +381-35-8102-060

Tel: +381-60-3584-888

My wife

Slavica Stojanović

+381-69-1601-977

Sindjelićeva 3/10

35230 Ćuprija

Serbia